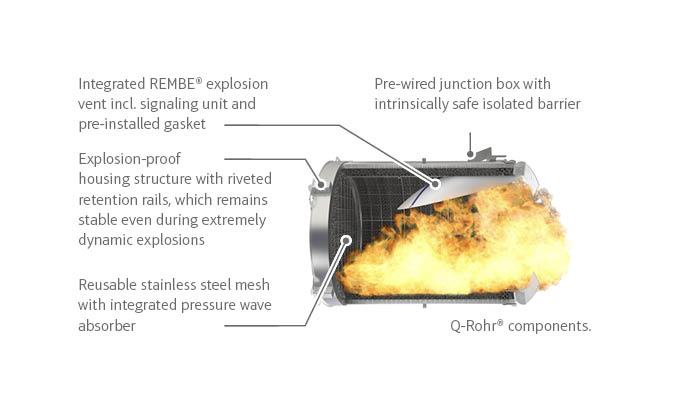

REMBE®Q-ROHR flameless venting

Related economic sectors

Agricultural

AgriculturalSafe and cost-effective solution for indoor applications

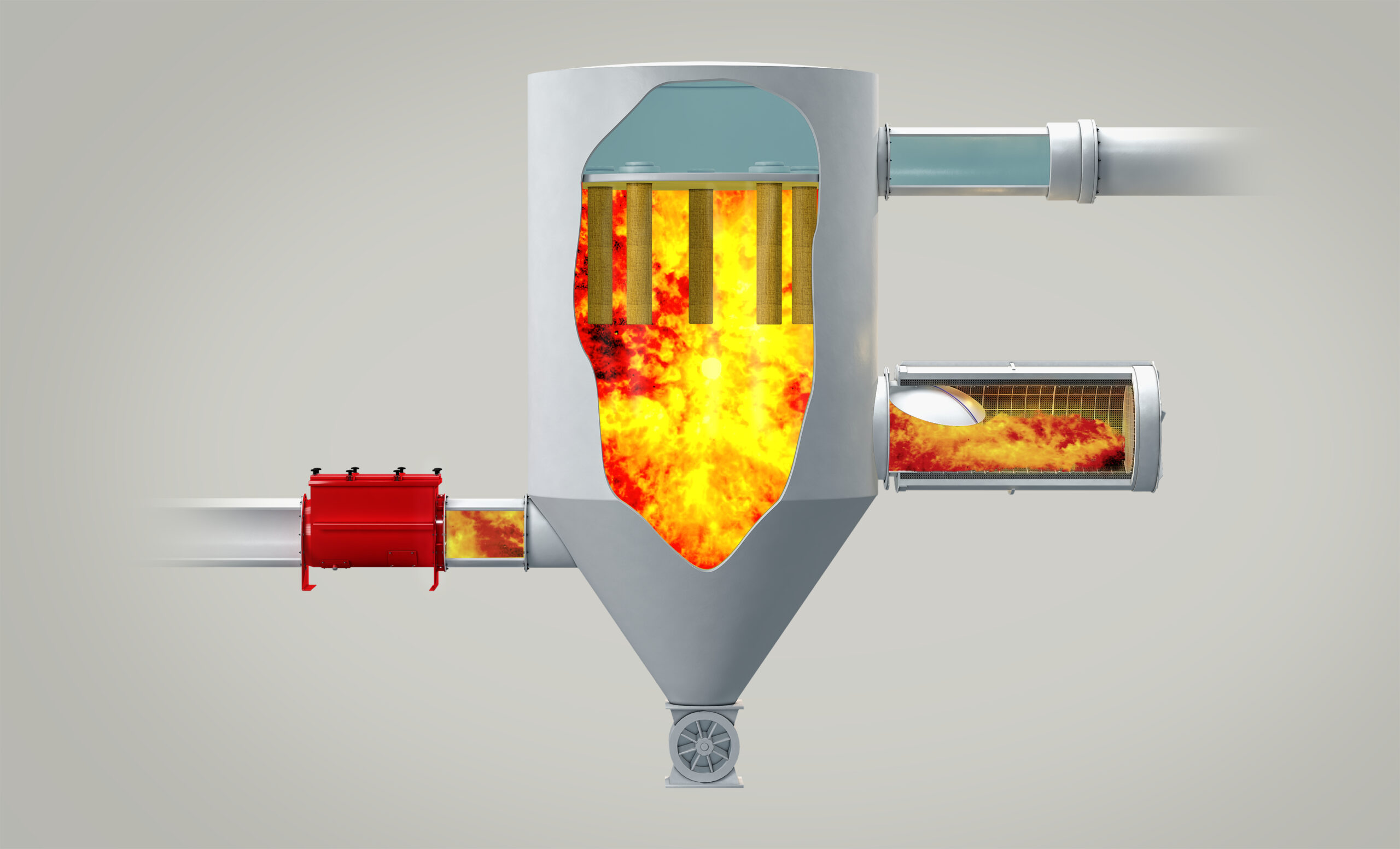

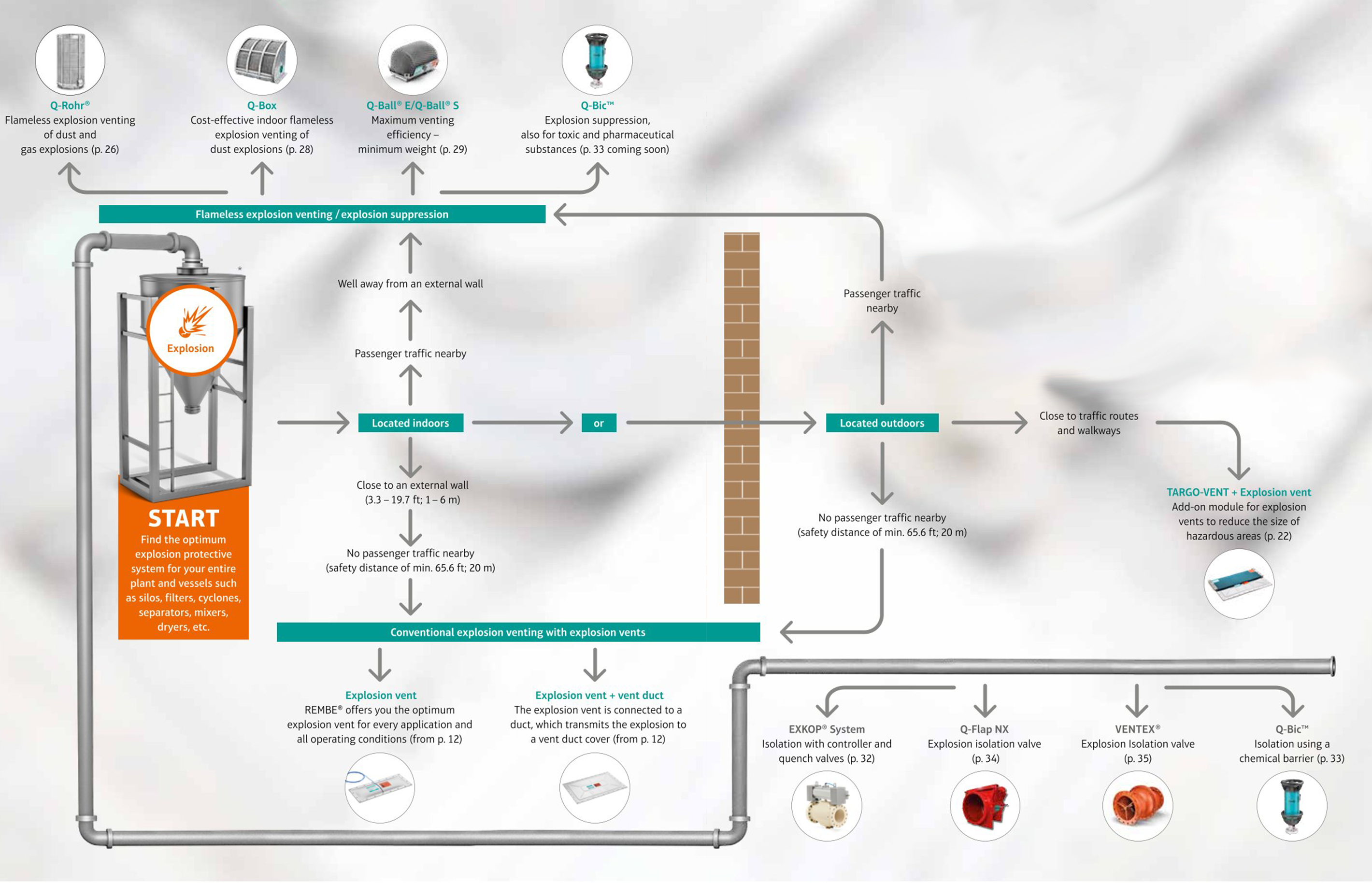

Safety and operating efficiency go hand in hand. The Q-Rohr® enables you to implement flame arresting and particulate retention explosion venting in closed rooms. No complicated ducts for outdoor venting or associated restructuring of production equipment are required. With the Q-Rohr® there is now nothing to prevent you from using the optimum layout for your production plant while guaranteeing the best possible explosion safety. In addition, Q-Rohr® is unrivaled in terms of running costs. Eliminating vent ducts saves you money not only on installation but also on servicing and maintenance. Q-Rohr® is also suitable for metal dusts, gas and hygienic applications. Q-Rohr® is available in the sizes DN 200 to DN 800. Customised versions up to DN 1400 are also possible.

The Q-Rohr® is ideal for indoor plants that are at risk of dust and gas explosions. Many new plants are equipped directly with the Q-Rohr® as it offers a wide range of flexible installation options. Retrofitting is also simplicity itself. The Q-Rohr® can be used to protect filters, dryers, cyclones and can be used with gases, hybrid mixtures, metal dusts, melting dusts or fibres.

Product specifications

Advantages

- Noise level and rise of pressure typically associated with explosions are greatly reduced to an acceptable harmless level.

- Immediately reusable and operational after cleaning of the filter and replacement of the explosion vent.

- Process-optimised plant layout.

- No external maintenance costs.

Mechanism

Options

- Optional sanitary cover prevents accumulation / contamination of the Q-Rohr® flame trap mesh in dusty areas.